3D printing service, in any case also labeled additive manufacturing, as acclaimed by production businesses. The concern is turning out to be a direct result of a part of the reformist focal points which it can provide. Like basically all advancements it has some hindrances that need consideration.

Advantages of additive manufacturing.

This creation cycle provides a range of favorable circumstances contrasted with traditional production strategies. These favorable conditions join those related to arrangement, time, and cost, among others.

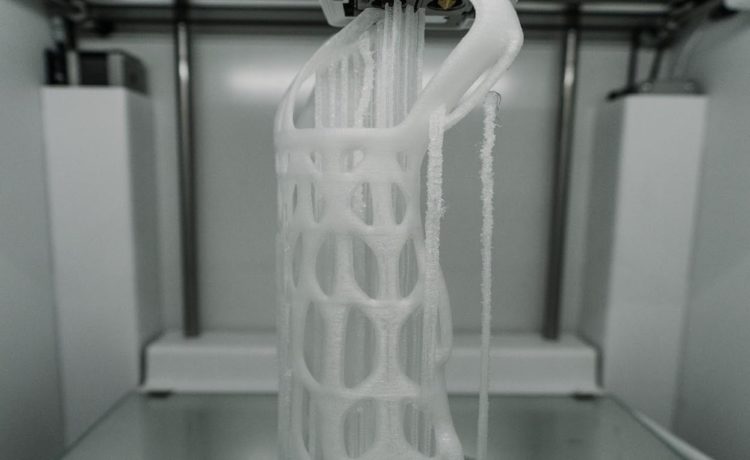

Resilient Design.

Custom 3D printing takes into account the plan and print of much intricate plans than custom manufacturing measures. More customary cycles have plan limitations that presently don’t have any significant bearing with the employment of 3D printing services.

Fast Prototyping.

Custom 3D printing service can produce parts in a short period even in hours, which makes it important in the prototyping cycle. This considers each stage to finish rapidly. When contrasted with machining models, custom 3D printing is cheap furthermore, speedier at creating parts as these parts may be possible in hours, considering each arrangement change in accordance with being done at a significantly more efficient rate.

On request Printing.

Print on solicitation is another favorable point as it does not require plenty of places to put stock, not as traditional manufacturing measures. These extras spaces and costs as there is no convincing motivation to print in horde aside from whenever required.

The 3D plan documents are completely put away in a virtual library as they are printed utilizing a 3D model as either a CAD or STL document, this implies they can be found and printed when required. Alters to plans can be made at low expenses by altering singular documents without wastage of outdated stock and putting resources into apparatus.

Solid and featherweight Parts.

The fundamental 3D printing material utilized is plastic, albeit a few metals can likewise be utilized for custom 3D printing. Be that as it may, plastics offer points of interest as they are featherweight in comparison to their metal counterparts. This is particularly critical in undertakings, for instance, cars, also, flying where featherweight is a vital issue and can pass on more unmistakable eco-neighborliness.

Additionally, parts can be made from custom-fitted materials to give explicit properties, for example, heat obstruction, higher strength, or water repellency.

Fast manufacturing cycle and speedy plan.

Detachment upon a chunk plan and multifaceted nature, custom 3D printing service can print an article in a short time even in hours, that is a much quicker than shaped or then again machined parts. It isn’t only the creation of the part that can offer time investment funds through 3D printing yet additionally the planning cycle can be exceptionally fast by making STL or CAD documents fit to be printed.

Saving cost reduction in Waste.

The creation of parts just requires the materials required for the part itself, with practically no wastage when contrasted with elective strategies which are cut from huge lumps of non-recyclable materials. Not exclusively does the cycle save money on assets however it additionally diminishes the expense of the materials being utilized.

Financially savvy.

As a solitary advance assembling measure, custom 3D printing spares time and in this manner costs related to utilizing various machines for making. 3D printers can likewise be set up and left to continue ahead with the work, implying that no requirement of humans will operate them to be available the whole time. This production cycle can likewise diminish costs on materials as it just uses the measure of material needed for the part itself, with next to zero wastage. While custom 3D printing hardware can be costly to get, you can even keep away from this expense by re-appropriating your task to a custom 3D printing organization.

Ecological Friendly.

As this innovation diminishes the measure of material wastage utilized this cycle is naturally ecological friendly. Nonetheless, the ecological advantages are broadened when you consider factors, for example, improved eco-friendliness from utilizing featherweight 3D printed parts.